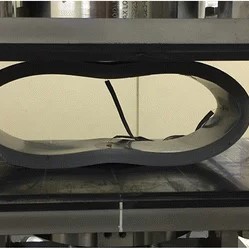

Bend test

Bend testing is a mechanical test used to evaluate the ductility, strength, and overall structural integrity of materials, particularly metals. This test involves bending a specimen to assess how it behaves under stress and to determine its ability to withstand deformation without cracking or breaking. Bend tests are commonly used in quality control, material selection, and research and development.